Technology Development

- Technology Market Review

- Technology Trials

- ATSP Site Selection

- ATSP Engineering Design

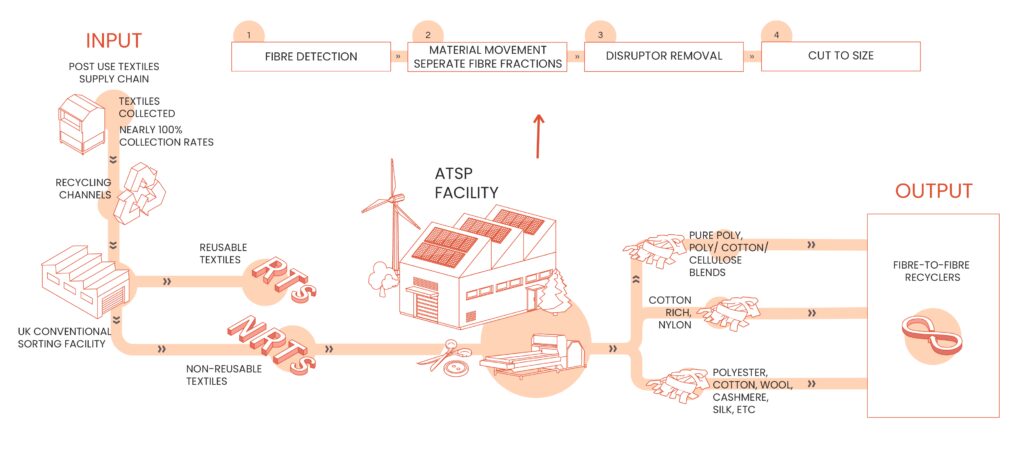

The key challenge ACT UK is looking to overcome is the sorting and pre-processing of textiles at a large scale. To do that, we have undertaken a state-of-the-art and market review of existing and emerging technologies for advanced textile identification, conveyance methods, and pre-processing technologies. This data will inform the development and design of a blueprint for the Automated Textile Sorting and Pre-processing facility design, which is being led by key consortium partner, Circle-8 Textile Ecosystems, supported by the Manufacturing Technology Centre (MTC).

During the course of the project, we will trial commercially available and high Technology Readiness Level (TRL) to efficiently sort and pre-process high volumes of NRT to:

- Inform the selection of the best available solutions to be implemented in the Automated Textile Sorting and Pre-processing (ATSP)

- Identify opportunities to accelerate the development and implementation of these technologies at a large scale

Technology Market Review

As part of the project, we are looking to fill the gap between recyclers and technology providers by reviewing the commercially available technology for conveyance, fibre identification, size reduction and disruptor removal (such as zips, buttons etc.) and their effectiveness in automatically sorting and pre-processing large volumes of non-rewearable textiles.

Continuing with the review of the latest technologies, we have prepared the Emerging Technologies Report. This report addresses challenges with low Technology Readiness Level (TRL technologies and highlights innovations that can improve efficiency and inspire new solutions for future iterations of the ATSP.

Request the Technology Market Review document

There is generally not a one-size-fits-all solution for any of the technology areas, and each technology area has challenges that require further research and development to resolve. The project consortium will work together to identify opportunities and trials to improve the ATSP process and provide insight into the direction of the textiles recycling industry.

Request the Emerging Technologies report

A brief overview of the findings from the review are:

- Horizontal belt conveyors are the industry standard for textile transport, but pneumatic options may offer an improvement dependant on the materials size and what processes have been completed.

- Although fibre identification is a well-developed technology area, current methods of placing textiles onto the conveyor system is highlighted as a bottleneck of the process.

- Disruptor removal is an area that has not seen many textile-specific developments. Two key types of machines, tearing machines with density/magnetic separation, and ballistic separators which have been used successfully in municipal waste and are now being configured for textiles. However, resulting yields and “quality” of the textile pose concerns for providing recyclers with high-quality feedstock at large volumes.

- Size reduction poses a challenge surrounding feedstock specifications for recycling, namely chemical recycling. Although many technology providers believe they can configure their equipment to produce feedstock to the specification required, further collaboration between recyclers and technology providers could see rapid developments in this area.

Technology Trials

The project team will also be assessing various equipment combinations and digitally simulating the ATSP facility under different operational scenarios. These trials will identify opportunities to accelerate the development and implementation of these technologies on a large scale. The results will inform the engineering design of the ATSP, ensuring it meets the requirements of textiles recyclers in the future.

ATSP Site Selection

UKFT and Circle-8 created the ATSP site brief and specifications that was distributed to key stakeholders, including regional authorities, innovation parks and retailers. The team is pleased to have received multiple proposals from different regions across the UK for the ATSP sites, which are currently being reviewed.

ATSP Engineering Design

Circle-8 and TOMRA textiles, a TOMRA-initiative dedicated to transformative solutions for textile circularity, are collaborating for the ATSP engineering process and facility design, with a focus on achieving efficiency and scalability.